07/09/2023

Revolutionizing Manufacturing with Edge AI: Insights from AI-PROFICIENT WP2

In the fast-evolving landscape of Industry 4.0, the AI-PROFICIENT project stands at the forefront of innovation, pioneering the integration of local AI technologies at the system’s edge. In this blog post, Aitor Arnaiz (TEK), Kerman Lopez de Calle (TEK), Alexandre Voisin (UL), and Vassilis Spais (INOS) dive deep into the Deliverable D2.6 ‘Smart components and local AI at system edge’, a report that encapsulates the activities and milestones achieved within Work Package 2 (WP2) of our project.

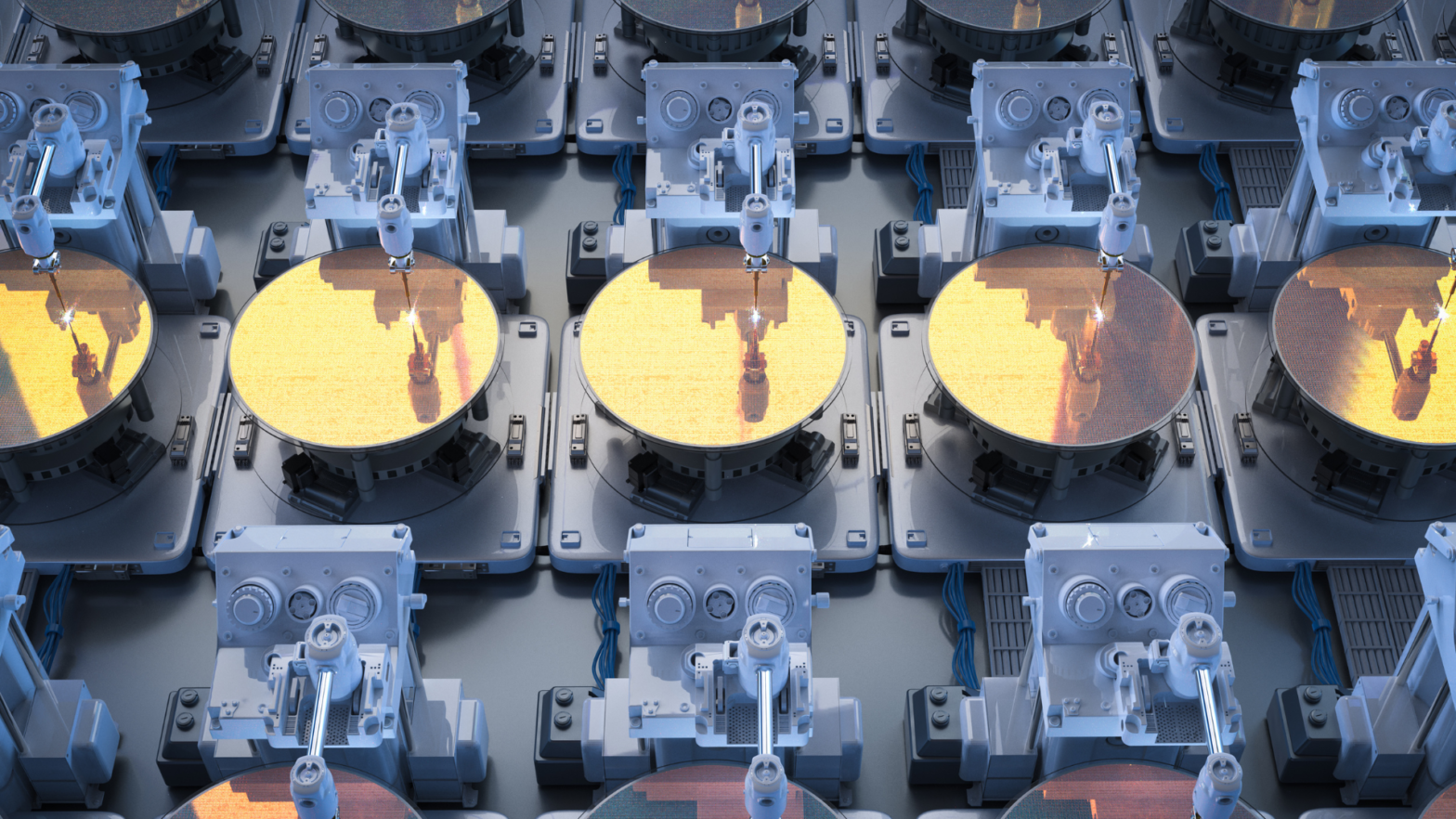

In specific, WP2 has played a crucial role by introducing local AI technologies at the system edge, a concept known as ‘smart components’. Unlike many AI technologies that typically operate at the cloud level, WP2 has focused on bringing AI closer to the production lines, harnessing data from Micro-Electromechanical Systems (MEMS) and Programmable Logic Controllers (PLCs) information outputs.

The AI-PROFICIENT team summarises and pinpoints four key technology applications within the realm of local AI at the system edge:

- AI Pre-processing Algorithms: These algorithms are instrumental in cleaning, aggregating, and filtering raw data, including image data and dense 3D position data (e.g., point clouds). The processed data is transformed into low cardinality vectors, serving as inputs for industrial maintenance support systems.

- Self-Diagnostics and Component Condition Estimation: Diagnosis strategies for asset monitoring and how AI can enhance these strategies. Notably, this implies that assets themselves can generate diagnostic information, updating as needed.

- Prognostics: Focusing on degradation-based prognostics, this application involves making projections about an asset’s future. It predicts not only the remaining useful life (RUL) but also the asset’s degradation trajectory. This combines AI techniques with conventional approaches like stochastic processes and time series models.

- Field Automated Control Mechanisms: These mechanisms enable real-time responses and adaptability based on the current condition of controlled assets.

At the same time, the report delves into the practical application of these technologies across seven different use cases within the Industrial IoT environment. Each use case is structured to differentiate the technologies under research, describes the use case itself, proposes a solution based on the chosen technological approach, and provides essential details regarding solution deployment.