14/06/2022

New Publication: Towards a circular rotating blade wear assessment digital twin for manufacturing lines

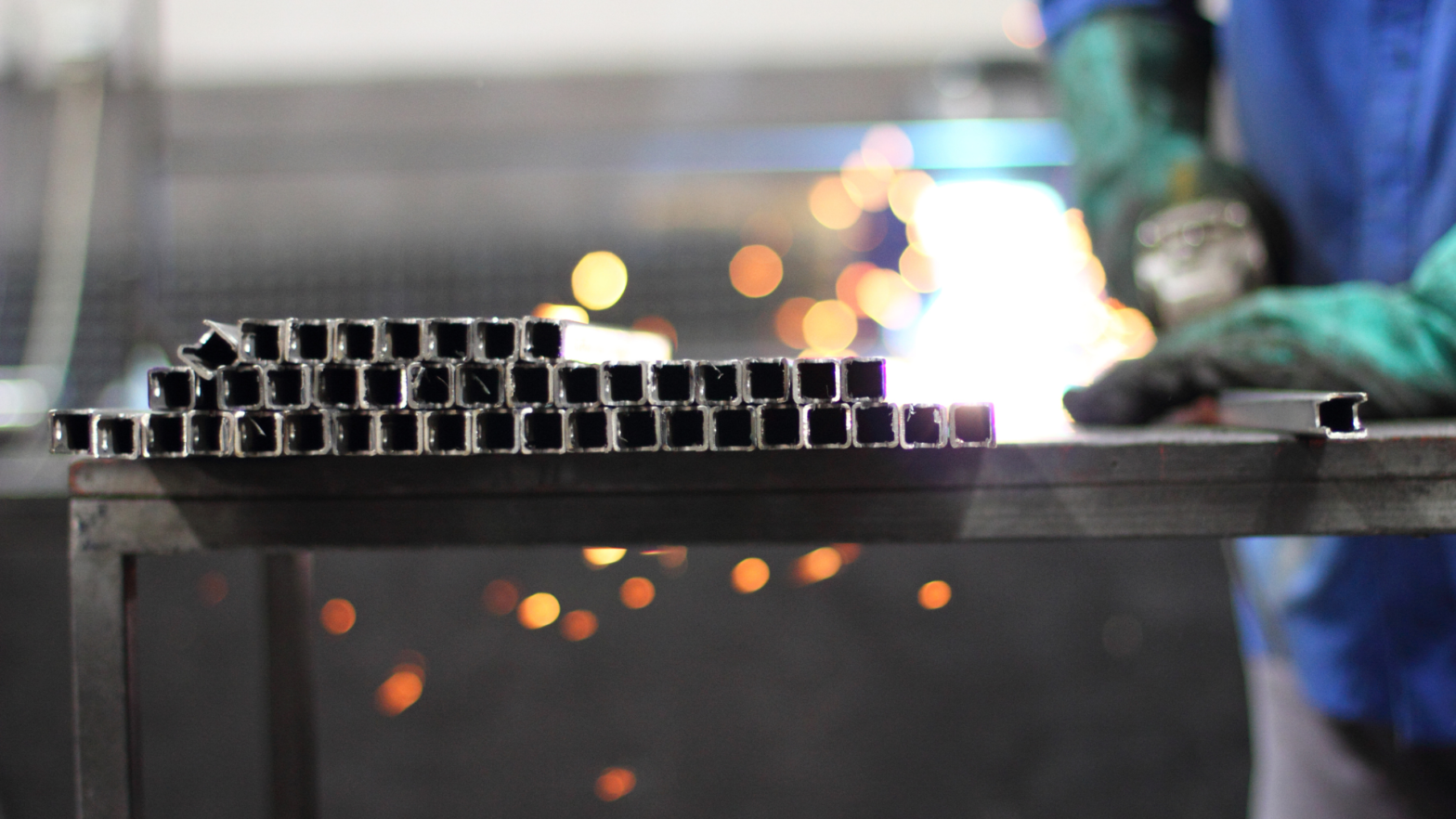

Circular blades are well known in sawmills and other fabrication sites, such as tyre industries. The cutting process produces wear on the blades, which gradually decreases the quality of the goods being cut, and, ultimately, this might cause the stoppage of the production line.

At the same time, since there are many factors affecting the cutting process and the direct inspection of wear is not practical, is not easy assessing the wear of the blades to avoid these quality losses and breakdowns.

In the publication ‘Towards a Circular Rotating Blade Wear Assessment Digital Twin for Manufacturing Lines’ López de Calle, Etxabe Kerman, Garate – Perez Eider and Arnaiz Aitor propose the development of a Digital Twin that is linked to the manufacturing line.

In specific, the twin includes a wear model that is based on the data generated in the line, and, as a result it can be used to identify the wear status of the blade, as well as to prognose the development of that wear based on future cutting schedules.

We must point out that this publication is very interesting because holistic blade cutting physical models are complex, and tend to be hardly extrapolable from laboratory validation to manufacturing sites, while the AI-Proficient team’s proposed method is based on the bottom up approach. This means that a simple wear model is deployed and linked to the manufacturing site and is then tuned through optimization with onsite data.

Last but not least, the authors pinpointed ‘the consideration of different usage patterns through a blades life allows a better prognostic of life estimation and scheduling of productions, which provides greater insight than other widely used data-based models such as the ones based on reliability’.